CH-SCW2500 Stored energy spot welding machine

- Tags:

CH-SCW2500 Stored energy spot welding machine

CH-SCW2000 Stored energy spot welding machine

Microcomputer the capacitor discharge point, Butt Welder Features: 1 by the CPU is the core of the control circuit, the charging voltage lock function, high precision voltage; 2 all-digital display and control, more intuitive, more comfortable, better welding effect, more stable operation; optional PLC microcomputer control system, the operating window; 3. Use of imported acute charging capacity, discharge time of 1/1000 second, charging time of 0.8 seconds, the work efficiency is greatly improved, and 50% or more energy-efficient than the average welder, is more suitable for the 24 hours of work; 4 is fast discharge, after the product is completed without yellow, not black, particularly suitable for a high electric conductivity of the non-ferrous metals, silver, aluminum, copper, etc.; 5 high-speed charge-discharge voltage regulator circuit, per minute up to more than 60 times the voltage error of ± 1%; 6. Imported pneumatic components, ensure that each pressure line; 7. Preload and compression short circuit protection.

Main technical parameters:

Model Method Input Power Output Capacitance Max Pressure Stroke Throat Dimension Cooling Water Volt/Phase KVA WS µF KG MM HXD MM LIT./Min SCW-2000 SPOT 380/2ø 2 500 4500 120 50 75X140 _ SCW-CD-2000 2 500 4500 120 50 75X140 _ SCW-3000-SP 3.5 1500 13500 3.5 50 75X140 _ SCW-3000 SPOT/ PROJECTION 380/2ø 3.5 1500 13500 300 80 160X450 Min.2 SCW-5000 5 3000 27000 300 80 160X450 Min.3 SCW-7000 7 4500 40500 500 80 220X380(500) Min.3 SCW-10K 10 6000 55500 1000 100 250X430(700) Min.6 SCW-15K 15 8000 73500 1500 100 250X430(700) Min.6 SCW-18K 18 12000 108000 1500 100 250X430(700) Min.10 SCW-20K 20 15000 135000 2000 100 250X430(700) Min.10

![]()

Tel:86-755-29059861 E-mail: info@heaterchina.com

Related Blog

Nozzle for for CSM Kanthal oakley tubular heater filling machine

Nozzle for for CSM Kanthal oakley tubular heater filling machineNozzle for CSM Kanthal oakley tubular heater filling machine

Die sealant for heating element filling machine

Die sealant for heating element filling machineDie sealant for heating element filling machine

principal axis for tubular heater rolling mill machine

principal axis for tubular heater rolling mill machineprincipal axis for tubular heater rolling mill machine

Tungsten carbide winding rod

Tungsten carbide winding rodTungsten carbide winding rod

Nozzle for heating element filling machine production manufactur in china

Nozzle for heating element filling machine production manufactur in chinanozzle for tubular heater mgo filling machine production manufactur in china

The main suit for heating element for skinning machine

The main suit for heating element for skinning machineThe main suit for heating element for skinning machine

Mandrel for heating wire tubular heater coiling Winding machine

Mandrel for heating wire tubular heater coiling Winding machineMandrel for heating wire tubular heater coiling Winding machine

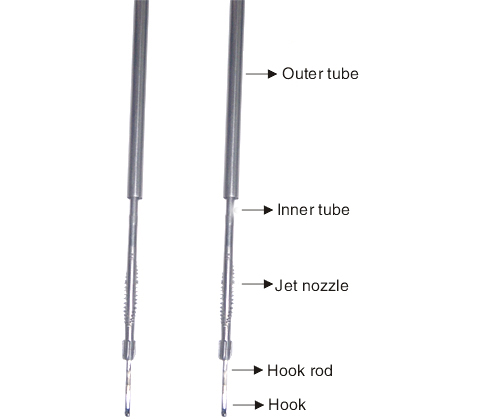

JET Nozzle filling set for tubular heater filling machine

JET Nozzle filling set for tubular heater filling machinefilling set for mgo powder filling machine

SKD11 rollers for CSM Kanthal oakley tubular heater rolling mill machine

SKD11 rollers for CSM Kanthal oakley tubular heater rolling mill machineSKD11 rollers for CSM Kanthal oakley tubular heater rolling mill machine

2hole Nozzle for cartridge heater filling machine

2hole Nozzle for cartridge heater filling machine2hole Nozzle for cartridge heater filling machine

Chamferring wheel for terminal pin chamferring machine

Chamferring wheel for terminal pin chamferring machineChamferring wheel for terminal pin chamferring machine